SDY355 BUTT FUSION Welding MACHINE OPERATION Manual

Tsanangudzo Yakakosha

Asati ashandisa muchina, chero munhu anofanirwa kuverenga tsananguro iyi nekuchenjerera uye kuichengeta zvakanaka kuti ave nechokwadi chekuchengetedzwa kwemudziyo uye kuchengetedzwa kwemushandisi, pamwe nekuchengetedzwa kwevamwe.

2.1 Muchina uyu unoshandiswa kubatanidza pombi dzakagadzirwa kubva kuPE, PP, PVDF uye haugone kushandiswa kugadzira zvinhu pasina tsananguro, zvikasadaro muchina unogona kukuvara kana imwe tsaona ingakonzereswa.

2.2 Usashandise muchina uri panzvimbo ine njodzi inogona kuputika

2.3 Muchina uyu unofanirwa kushandiswa nevashandi vane mutoro, vane hunyanzvi uye vakadzidziswa.

2.4 Muchina unofanirwa kushandirwa panzvimbo yakaoma. Matanho ekudzivirira anofanira kutorwa kana ashandiswa mumvura inonaya kana pavhu rakanyorova.

2.5 Muchina uyu unoshanda ne220V±10%, 50Hz. Kana tambo yakatambanudzwa ikashandiswa, inofanira kuva nechikamu chemutobvu chakakwana maererano nehurefu hwayo.

2.6 Usati washandisa muchina, zadza 46# hydraulic mafuta. Iva nechokwadi chokuti hydraulic mafuta yakakwana kushanda; chiyero chemafuta chinofanira kunge chiri 2/3 yetangi. Tsiva chivharo chetangi yesimbi nekaputi tsvuku yemhepo inobuda ropa kana kudzvanywa hakugone kubatwa.

Safety

3.1 Chengetedza kana uchishanda uye kutakura muchina zvinoenderana nemitemo yese yekuchengetedza mune iyi rairo.

3.1.1 Cherechedza paunenge uchishandisa

l Mushandi anofanirwa kuve nehanya uye akadzidziswa vashandi.

l Nyatsoongorora uye chengetedza muchina pagore kuitira kuchengetedza uye kuvimbika kwemuchina.

l Nzvimbo yebasa yakasviba uye yakakomberedzwa haingodzikisi kushanda zvakanaka, asi kukonzera tsaona nyore, saka zvakakosha kuchengetedza nzvimbo yebasa yakachena uye pasina zvimwe zvipingamupinyi.

3.1.2 Simba

Bhokisi rekugovera magetsi rinofanirwa kunge riine chigumbuso chepasi chine chiyero chekuchengetedza magetsi. Yese midziyo yekudzivirira inoratidzirwa nemashoko anonzwisisika kana mamaki.

Earthing: Iyo saiti yese inofanirwa kugovera imwechete pasi waya uye yepasi yekubatanidza system inofanirwa kupedzwa uye kuedzwa nevanhu vane hunyanzvi.

3.1.3 Kubatanidzwa kwemuchina kumagetsi

Iyo tambo yekubatanidza muchina kune simba inofanirwa kunge iri mechanical concussion uye chemical corrosion proof. Kana tambo yakatambanudzwa yakashandiswa, inofanira kuva nechikamu chakakwana chekutungamira maererano nehurefu hwayo.

3.1.4 Kuchengeta midziyo yemagetsi

Nokuti min. njodzi, zvishandiso zvese zvinofanirwa kushandiswa uye kuchengetwa nemazvo sezvinotevera:

※ Regedza kushandisa waya yenguva isingaenderane neyakajairwa

※ Usabate electrophorus zvikamu

※ Rambidza kudhonza kubva patambo kuti ubvise

※ Rambidza kudhonza tambo dzemidziyo yekusimudza

※ Usaise chinhu chinorema kana chakapinza patambo, uye kudzora tembiricha yetambo mukati mekudzikamisa tembiricha (70 ℃)

※ Usashande munzvimbo ine mvura. Tarisa kana groove neshangu zvaoma.

※ Usasasa muchina

3.1.5 Tarisa mamiriro ekudzivirira emuchina nguva nenguva

※ Tarisa kuvharwa kwetambo kunyanya mapoinzi akawedzerwa

※ Usashandise muchina uri pasi pemamiriro akanyanya.

※ Tarisa kana iyo leakage switch ichishanda zvakanaka kanenge pasvondo.

※ Tarisa pasi pemuchina nevashandi vanokwanisa

3.1.6 Geza uye tarisa muchina nemazvo

※Usashandise zvinhu (senge abrasive, uye zvimwe zvinonyungudutsa) zvichikuvadza kuvharisa zviri nyore paunenge uchichenesa muchina.

※ Ita shuwa kuti simba rakabviswa kana wapedza basa.

※ Ita shuwa kuti hapana kukuvadzwa mumushini usati washandisa zvakare.

Kana kungotevera zvataurwa pamusoro apa, kungwarira kunogona kushanda zvakanaka.

3.1.7 Kutanga

Ita shuwa kuti switch yemuchina yakavharwa usati waibatisa.

3.1.8 Munhu asina kudzidziswa haabvumidzwe kushandisa muchina chero nguva.

3.2.Njodzi dzinogona kuitika

3.3.1 Butt fusion muchina unodzorwa nehydraulic unit:

Muchina uyu unongoshandiswa nemunhu ane hunyanzvi kana vamwe vane chitupa chekushanda, zvikasadaro njodzi yausingadi inogona kukonzerwa.

3.3.2 Ndiro yekudziya

Iyo tembiricha yepamusoro inogona kusvika 270 ℃, saka zvinotevera zvinhu zvinofanirwa kucherechedzwa:

------Pfeka magirovhosi ekuchengetedza

-------Usambofa wakabata pamusoro pendiro yekudziya

3.3.3 Kuronga mudziyo

Usati waveura mapaipi, migumo yepombi inofanira kucheneswa, kunyanya kuchenesa jecha kana imwe dhizaini yakarira kumativi. Nekuita izvi, hupenyu hwemupendero hunogona kurebeswa, uye zvakare kudzivirira shavings inokandwa kunze kune njodzi vanhu.

3.3.4 Basic Frame:

Ita shuwa kuti mapaipi kana mafittings akagadziriswa nemazvo kuti awane kurongeka chaiko. Pakujoinha mapaipi, mushandisi anofanira kuchengetedza imwe nzvimbo kumuchina kuitira kuchengetedza vashandi.

Usati watakura, ita shuwa kuti mabhanhire ese akagadziriswa zvakanaka uye haagone kudonha panguva yekufambisa.

Tevedzera ese mavanga ekuchengetedza mumushini.

Tsanangudzo

Muchina uyu une basic frame, hydraulic unit, heat plate, planing tool uye rutsigiro.

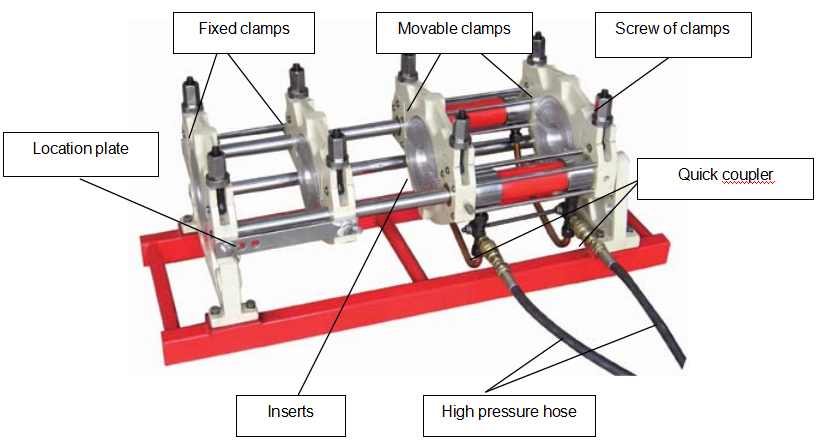

5.1 Frame

5.2 Chishandiso chekuronga uye kupisa ndiro

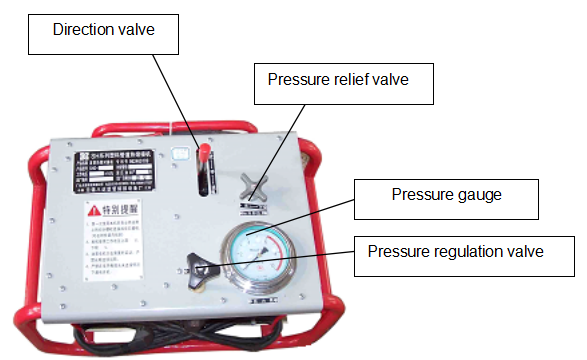

5.3 Hydraulic unit

Murayiridzo Wekushandisa

6.1 Midziyo yese inofanirwa kuiswa pane yakatsiga uye yakaoma ndege kuti ishande.

6.2 Usati wavhiya ita shuwa zvinhu zvinotevera:

u Mushini uri mumamiriro akanaka

u Simba rinoenderana nezvinodiwa zvinoenderana nebutt fusion muchina

u Power line haina kuputswa kana kupfekwa

u All zviridzwa zvakajairika

u Mashizha emudziyo wekuronga akapinza

u Zvese zvinodiwa zvikamu uye zvishandiso zviripo

6.3 Kubatanidza uye kugadzirira

6.3.1 Batanidza iyo basic frame kune hydraulic unit nevanokurumidza couplers.

6.3.2 Batanidza mutsara weplate yekudziya kubhokisi remagetsi mune hydraulic unit.

6.3.3 Batanidza tambo yekudziya ndiro yekudziya ndiro.

6.3.4 Isai zvinoiswa zvakakodzera kuti ifreyimu zvinoenderana nedhayamita rekunze repombi/mafittings.

6.3.5 Zvinoenderana nezvinodiwa zvefitting uye welding process, isa tembiricha mutembiricha controller uye isa nguva mu timer. (Ona chikamu chechinomwe chebhuku rino).

6.4 Welding matanho

6.4.1 Mapaipi

Usati welding, chekutanga, tarisa kana zvinhu uye giredhi yekumanikidza zviri izvo zvinodiwa. Chechipiri tarisa kana paine makwara kana mafissure pamusoro pepombi/mafittings. Kana kudzika kwekukwenya kana kutsemuka kuchipfuura 10% yehukomba hwemadziro, cheka chikamu chezvikwambo kana fissures. Chenesa nzvimbo dzepombi nejira rakachena kuti mativi epombi agare akachena.

6.4.2 Kurovera

Isai mapaipi / mafittings mukuisa kwefuremu uye chengetedza magumo kuti ave welded akaenzana kureba (hapana chazvinoita pakuronga nekudziya kwepombi). Iyo pombi kunze kweiyo yakakosha furemu inofanirwa kutsigirwa kune imwecheteyo yepakati axial yezvisungo. Sunga mascrews emagetsi kugadzirisa mapaipi / mafittings.

6.4.3 Gadzirisa kumanikidza

Vhura zvizere vharuvhu yekudzora kumanikidza zvachose, kiya cheki cheki vharafu zvakasimba uye wobva wasundidzira kumberi kwevhavha yekutungamira panguva iyi gadzirisa vhavha yekudzora dhiza kusvikira silinda yatanga kufamba, panguva ino kudzvanywa muhurongwa ndiko kudhonza.

Vhura vhavha yekudzora dhizaini zvachose, kiya iyo swing cheki vharafu zvakasimba uye wobva wasundidzira kumberi vheji yekutungamira panguva iyi gadzirisa iyo yekumanikidza regulation vharafu kuti uise iyo system yekumanikidza yakaenzana nekudhonza kudhonza kuwedzera butting pressure.

6.4.4 Kuronga

Vhura mapaipi / mafittings anopera mushure mekushandura swing cheki vharafu anti-clockwise kusvika kumagumo. Isa mudziyo wekuronga pakati pemapombi/mafitsi anogumira uye woibatidza, vhara mapaipi/mafittings anogumira nekuita pane gwara vharafu ukuwo zvishoma nezvishoma shandura swing cheki cheki vharafu kusvika paine mashavings anoramba achionekwa pamativi ese. Shandura swing valve anti clockwise kuti usunungure kudzvanywa, munguva pfupi gare gare vhura furemu, dzima chishandiso chekuronga uye ubvise.

Vhara mapaipi / akakodzera magumo uye tarisa kurongeka kwawo. Iwo maximal misalignment haifanire kudarika 10% yehukobvu hwemadziro, uye inogona kuvandudzwa nekusunungura kana kuomesa screws ye clamps. Mukaha pakati pemigumo yepombi mbiri haifanire kudarika 10% yemadziro emadziro; kana zvisina kudaro mapaipi / zvigadziri zvinofanira kurongwa zvakare.

Chenjedzo: Ukobvu hwemashavings hunofanira kunge huri mukati me 0.2 ~ 0.5 mm uye hunogona kugadziriswa nekugadzirisa hurefu hwemapuranga ekugadzirisa.

6.4.5 Kupisa

Bvisa guruva kana kutsemuka pamusoro pekudziya ndiro (Yambiro: Usakanganise PTFE layer pamusoro pekudziya ndiro.), uye ita shuwa kuti tembiricha yasvika painodiwa.

Isai kupisa ndiro pakati pepombi inopera mushure mokunge yasvika inodiwa tembiricha. Vhara mapaipi/mafittings anogumira nekushandisa nzira vharafu uye simudza kudzvanya kune yakatsanangurwa kudzvanywa nekupuruzira pressure regulation valve kusvika bead yasvika pahurefu hwakataurwa.

Shandura swing cheki vharafu kuti uderedze kudzvanywa (kwete kupfuura kudhonza) uye shandura swing cheki vharafu munzira yewachi kusvika kumagumo.

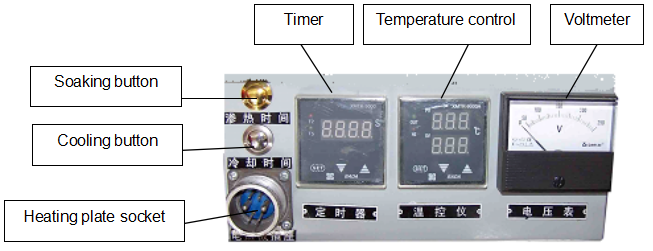

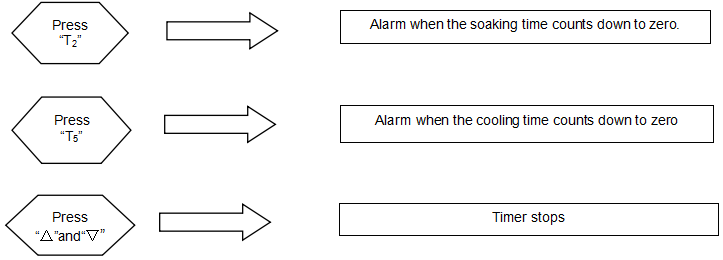

Dzvanya bhatani "T2”, iyo nguva yekunyura inotanga kuverenga uye nguva ichaverengera kusvika zero nesekondi, ipapo buzzer ichaita ruzha (ona chikamu 7)

6.4.6 Kujoinha nekutonhodza

Vhura furemu uye bvisa ndiro yekudziya uye vhara maviri anonyungudika nekukasira.

Chengetedza bhawa revhavha yekutungamira panzvimbo yepedyo ye2 ~ 3 maminetsi, isa bhawa rekutungamira vharafu panzvimbo yepakati uye tinya bhatani ("T5") kuverenga nguva yekutonhora kusvika yapera. Panguva ino, muchina uchapa alarm zvakare. Rerutsira kudzvanywa, sunungura sikuruu yezvisungo wobva watora mapaipi akabatanidzwa.

Timer uye Temperature Controller

Kana imwe yeparameter ichishandurwa, senge dhayamita yekunze, SDR kana zvinhu zvepombi, nguva yekunyura uye nguva yekutonhora inofanira kugadziridzwa zvinoenderana neyakajairwa welding.

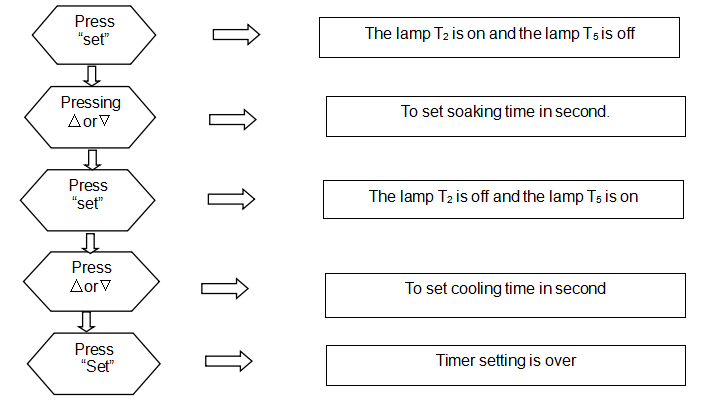

7.1 Kugadzirisa nguva

7.2 Murairo Wekushandisa

7.3 Tembiricha controller kuseta

1) Dzvanya "SET" kweanopfuura masekonzi matatu kusvika "sd" yaratidzwa pahwindo rekumusoro

+

3) Mushure mekuseta, tinya "SET" kuti udzokere kukutarisa uye kutonga interface

Reference yeWelding Standard (DVS2207-1-1995)

8.1 Nekuda kwekusiyana mune welding standard uye PE zvinhu, iyo nguva uye kudzvanywa zvinosiyana muzvikamu zvakasiyana zvewelding. Inoratidza kuti iwo chaiwo welding parameters anofanirwa kupihwa nemapombi uye ekugadzirisa 'vagadziri.

8.2 Yakapihwa welding tembiricha yepombi dzakagadzirwa kubva PE, PP uye PVDF neDVS chiyero siyana kubva180 ℃ kusvika 270 ℃. Kushandisa tembiricha yekudziya ndiro iri mukati me180~230℃, uye max yayo. pamusoro tembiricha inogona kusvika 270 ℃.

8.3 Reference standard DVS2207-1-1995

| Kukora kwemadziro (mm) | Bead urefu (mm) | Bead kuvaka-up pressure (MPa) | Kunyura nguva t2(sekondi) | Kunyura pressure (MPa) | Kuchinja-nekufamba kwenguva t3(sekondi) | Pressure kuvaka-up nguva t4(sekondi) | Welding pressure (MPa) | Nguva yekutonhodza t5(min) |

| 0~4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1.0 | 0.15 | 45~70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6~10 |

| 7~12 | 1.5 | 0.15 | 70~120 | ≤0.02 | 6~8 | 6~8 | 0.15±0.01 | 10~16 |

| 12~19 | 2.0 | 0.15 | 120~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16~24 |

| 19~26 | 2.5 | 0.15 | 190 -260 | ≤0.02 | 10~12 | 11~14 | 0.15±0.01 | 24~32 |

| 26~37 | 3.0 | 0.15 | 260~370 | ≤0.02 | 12~16 | 14~19 | 0.15±0.01 | 32~45 |

| 37~50 | 3.5 | 0.15 | 370~500 | ≤0.02 | 16~20 | 19~25 | 0.15±0.01 | 45~60 |

| 50~70 | 4.0 | 0.15 | 500~700 | ≤0.02 | 20~25 | 25~35 | 0.15±0.01 | 60~80 |

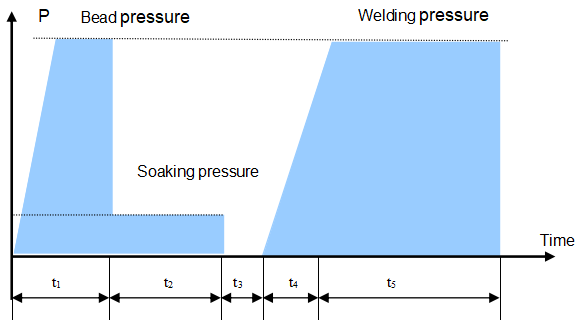

Ongorora: Bead kuvaka-up kumanikidza uye welding kudzvanywa mufomu ndiyo inokurudzirwa interface yekumanikidza, iyo geji yekumanikidza inofanirwa kuverengerwa neinotevera formula.

Matauriro:

Malfunctions Analyzes uye Solutions

8.1 Anowanzo sangana matambudziko emhando yekuongorora:

8.2 Nguva yekuchengetedza uye yekuongorora

8.2.1 Kuchengeta

※ Heating plate coating

Ndapota chenjerera kubata ndiro yekudziya. Chengetedza imwe chinhambwe kubva pakudziya ndiro. Kucheneswa kwepamusoro payo kunofanirwa kuitwa nepamusoro ichiri kudziya nekushandisa jira rakapfava kana bepa, dzivirira zvinhu zvinokuvadza izvo zvinogona kukuvadza coating.

Nguva nenguva tarisai sezvinotevera

1) Chenesa pamusoro nekushandisa kukurumidza evaporation detergent (doro)

2) Tarisa kuomeswa kwema screws uye tambo uye plug mamiriro

3) Simbisa tembiricha yayo yepasi uchishandisa infrared-ray scanning

※ Kuronga chishandiso

Zvinokurudzirwa kuti ugare wakachena mashizha uye kugeza mapulley nekushandisa detergent. Nguva nenguva, ita basa rekuchenesa rakakwana.

※ Hydraulic unit

Zvichengetedze sezvinotevera

1) Tarisa nguva nenguva huwandu hwemafuta

2) Tsiva mafuta zvachose mwedzi mitanhatu yega yega

3) Chengetedza tangi uye dunhu remafuta zvakachena

8.2.2 Kuchengeta & Kuongorora

Kuongororwawo zvako

| Item | Tsanangudzo | Wongorora usati washandisa | Chekutanga mwedzi | Mwedzi mitanhatu yese | Every gore |

| Planning tool | Chigayo kana kutsiva blade Dzorera tambo kana yatyoka Dzokorora kubatanidza kwemagetsi |

● ● |

● |

| ● ●

|

| Kupisa ndiro | Akabatanidza tambo uye socket Yakachena nzvimbo yekudziya ndiro, dzokorora PTFE layer zvakare kana zvichidikanwa Dzokorora kubatanidza kwemagetsi | ● ●

● |

● |

|

●

|

| Temp. control system | Checkout tembiricha chiratidzo Dzorera tambo kana yatyoka |

● |

|

| ● ● |

| Hydraulic system | Checkout pressure gauge Tsiva zvisimbiso kana iyo hydraulic unit yadeuka Chenesa sefa Iva nechokwadi chokuti mafuta anokwana kushanda Shandura iyo hydraulic mafuta Dzorera kana hose yemafuta yaparara |

● ● ● |

|

● | ● ●

● ●

|

| Basic Frame | Dzorera masiruuru mumagumo eforemu axis Pfaya antirust pendi zvakare kana zvichidikanwa | ●

| ●

| ●

|

● |

| Simba Supply | Dzvanya bhatani rekuyedza redunhu mudziviriri kuti uone kuti rinogona kushanda zvakajairwa Dzorera tambo kana yatyoka | ●

● |

|

● |

|

“●”………… nguva yekugadzirisa

9.3 Kakawanda kusashanda ongororo uye mhinduro

Panguva yekushandiswa, hydraulic unit uye magetsi mayuniti anogona kuoneka mamwe matambudziko. Kakawanda kusashanda zvakanaka kwakanyorwa sezvinotevera:

Ndapota shandisa maturusi akabatanidzwa, maspare parts kana mamwe maturusi ane chitupa chekuchengetedza uchichengeta kana kutsiva zvikamu. Zvishandiso uye zvikamu zvakasara zvisina chitupa chekuchengetedza zvinorambidzwa kushandiswa.

| Kusashanda zvakanaka kwehydraulic unit | |||

| No | kusashanda zvakanaka | malfunction analysis | Solutions |

| 1 | Iyo mota yepombi haishande |

| |

| 2 | Mota yepombi inotenderera zvishoma nezvishoma ine ruzha rusingaite |

| 1. Iva nechokwadi chokuti mutoro wemotokari uri pasi pe3 MPa 2. Gadzirisa kana kutsiva pombi 3. Geza sefa 4. Tarisa kusagadzikana kwesimba |

| 3 | Silinda inoshanda zvisina kujairika |

| |

| 4 | Cylinder leak | 1. Mhete yemafuta inokanganisa 2. Silinda kana piston yakakuvadzwa zvakaipa | 1. Dzorera mhete yemafuta 2. Dzorera humburumbira |

| 5 | Dzvinyiriro haigone kuwedzerwa kana kuchinjika kwakakurisa | 1. Nheyo yevhavha yekuyerera yakavharwa. 2. Pombi inobuda. 3. The joint slack yepombi yakasunungurwa kana key groove is skid. 4. Ivhavha yekudzivirira kudzvinyirira haina kuvharwa | 1. Chenesa kana kutsiva iyo core ye over-flow valve 2. Dzorera pombi 3. Tsiva mubatanidzwa slack 4. Kuvhara valve |

|

Kutadza kushanda kwemagetsi emagetsi | |||

| 1 | Mushini haushande |

| 1. Tarisa tambo yemagetsi 2. Tarisa simba rekushanda 3. Vhura pasi kukanganisa kukanganisa |

| 2 | Ground fault switch nzendo |

| 1. Tarisa tambo dzemagetsi 2. Tarisa zvinhu zvemagetsi. 3. Tarisa iyo yepamusoro-up simba rekuchengetedza mudziyo |

| 3 | Kuwedzera kwekushisa kusina kujairika | 1. The tembiricha controller switch yakazaruka 2. Iyo sensor (pt100) haina kujairika. Iko kukosha kwekupokana kwe4 uye 5 yekudziya ndiro socket inofanira kunge iri mukati me100 ~ 183Ω 3. Chimuti chekudziisa chiri mukati mekudziya ndiro hachisi kujairika. Kupikisa pakati pe2 ne3 kunofanira kunge kuri mukati me23Ω. Insulation resistance pakati pemusoro wetsvimbo yekudziya negoko rekunze kunofanirwa kunge kuri kupfuura 1MΩ 4. Kana tembiricha controller kuverenga ingapfuura 300 ℃, izvo zvinoratidza kuti sensor inogona kukuvara kana kubatana kwakasununguka. Kana iyo tembiricha controller inoratidza LL, izvo zvinoratidza kuti sensor ine pfupi dunhu. Kana iyo tembiricha controller inoratidza HH, iyo inoratidza kuti dunhu re sensor rakavhurika. 5. Gadzirisa tembiricha nebhatani riri pane tembiricha controller.

| 1. Tarisa kubatana kwemacontactor 2. Dzorera sensor

3. Dzorera ndiro inopisa

4. Tsiva tembiricha controller

5. Tarisa kune nzira dzekuseta tembiricha 6. Tarisa uye kutsiva contactors kana zvakakodzera |

| 4 | Kutadza kuzvidzora pakupisa | Chiedza chitsvuku chinopenya, asi tembiricha ichiri kukwira, imhaka yekuti chinongedzo chakanganisa kana majoini 7 ne8 haagone kuvhura kana awana tembiricha inodiwa. | Tsiva tembiricha controller

|

| 5 | Planning tool haitenderere | Iyo yekumisikidza switch haishande kana mekiniki zvikamu zveplaning tool zvakatemwa. | Tsiva iyo yekuronga chishandiso chekugadzirisa switch kana diki sprocket |