Revolutionizing Plastic Pipe Kuisirwa: Iko Kusimuka kweOtomatiki Plastic Pipe Welding Machines

Kunzwisisa Automatic Plastic Pipe Welding Machines

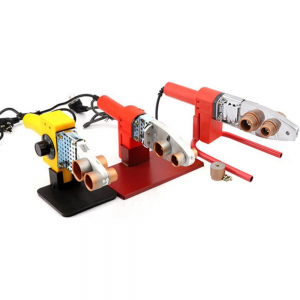

Otomatiki epurasitiki pombi welding michina midziyo yakaomesesa yakagadzirirwa kuchinjisa maitiro ekugadzira thermoplastic pombi, senge polyethylene (PE), polypropylene (PP), uye polyvinyl chloride (PVC). Michina iyi inosanganisa kupisa, kudzvanywa, uye kutonhora zvikamu pasi pekutonga chaiko, kuve nechokwadi chemhando yepamusoro welds nekupindira kushoma kwevanhu. Kubva pakuvandudzwa kwezvivakwa kusvika pakuisa zvekushandisa, otomatiki welding michina iri kuve yakakosha mumaindasitiri akasiyana.

Zvinhu Zvikuru uye Zvakanakira

●Kururamisa uye Kuenderana: Otomatiki kudzora masisitimu anovimbisa kuti weld yega yega inoitwa neyakaomesesa zviyero, kuderedza njodzi yekukanganisa kwevanhu uye kusiyanisa.

●Kuwedzera Kubudirira: Nekukurumidza kutenderera kutenderera uye kushoma kwemanyorero kuseta, mapurojekiti anogona kupedzwa nekukasira, achiwedzera kugadzirwa kwese.

●Data Logging uye Traceability: Mamodheru epamberi anopa ruzivo rwekutema data, achibvumira vashandisi kuti vatarise uye varekode welding maparamendi ekusimbisa kwemhando uye zvinangwa zvekuteerera.

●Mushandisi-Inoshamwaridzana Interface: Pasinei nekuoma kwavo, michina yemazuva ano inoratidzira intuitive interfaces, zvichiita kuti zvive nyore kune vashandisi kubata basa rewelding.

Kusarudza Kurudyi Otomatiki Plastic Pipe Welding Machine

Kusarudza yakanyatsokodzera otomatiki epurasitiki pombi welding muchina kunoda kunyatsotarisisa zvinhu zvakati wandei:

●Pipe Saizi uye Material Kuenderana: Ita shuwa kuti muchina unogona kugarisa huwandu hwepombi madhayamita uye zvinhu zvinoshandiswa mumapurojekiti ako.

●Welding Process Zvinodiwa: Michina yakasiyana inobata kune dzakasiyana-siyana welding maitiro (semuenzaniso, butt fusion, electrofusion). Sarudza muchina unoenderana nemaitiro ako chaiwo aunoda.

●Portability uye Site Conditions: Funga nezvekufamba kwemuchina uye kuchinjika kune akasiyana saiti mamiriro, kunyanya kumapurojekiti ari munzvimbo dzakaoma.

●Tsigiro yehunyanzvi uye Maintenance: Sarudza vagadziri vanopa yakazara tekinoroji rutsigiro uye nyore kuwana kune ekugadzirisa masevhisi kuve nechokwadi chekuvimbika kwenguva refu.

Zvishandiso uye Indasitiri Impact

Otomatiki epurasitiki pombi welding michina iri kushandura mashandiro muzvikamu zvakaita semvura netsvina manejimendi, kugovera gasi, uye maindasitiri pombi masisitimu. Nekugadzirisa maitirwo ewelding, michina iyi haingonatsiridza kukurumidza uye mhando yekumisikidza asiwo inobatsira mukurarama kwenguva refu uye kuchengetedzeka kwepombi network.

Maitiro Akanakisisa Okushandisa

Kuti uwedzere mabhenefiti e otomatiki epurasitiki pombi welding michina, tevedzera anotevera akanakisa maitiro:

●Kunyatsodzidziswa: Ita shuwa kuti vashandisi vanowana kudzidziswa kwakazara pane chaiyo modhi yemuchina wewelding kuti uwedzere kushandiswa kwayo uye kugadzirisa.

●Regular Calibration uye Maintenance: Chengetedza muchina uri muchimiro chepamusoro kuburikidza nekugadzirisa nguva dzose uye kuchengetedza kwekudzivirira, uchitevera kurudziro yemugadziri.

●Quality Control: Shandisa makina ekutema data maficha kutarisa weld mhando uye kugadzirisa sezvinodiwa kuchengetedza yakakwirira miitiro.

Mhedziso

Kuuya kweotomatiki epurasitiki pombi welding michina inomiririra yakakosha kusvetuka mberi mupurasitiki pombi yekuisa tekinoroji. Nekumbundira maturusi aya akaomarara, mabhizinesi anogona kuwana hunyanzvi hwepamusoro, hunhu, uye kuenderana mumabasa avo ekuwedha, vachizviisa pamberi pehunyanzvi hweindasitiri. Sezvo tekinoroji ichiramba ichishanduka, kugara uine ruzivo uye kuisa mari mumidziyo yakakodzera kuchave kwakakosha pakusimudzira kugona kwakazara kweautomation mupurasitiki pombi welding.